Electronic

Ground Power Units

February 20, 2019 by admin · Leave a Comment

Airplanes are grounded for minutes, sometimes hours at a time. The planes are shut off during this time to allow crews to perform diagnostics, and for the admission of passengers. As you sit down on the plane, you’ll notice lights come on and various mechanical noises come from the cabin. This is the normal sound of the airplane receiving a jumpstart and whirring to life. A ground power unit is needed to complete this procedure, giving the engines the spark they need to jolt to life.

Turbine Systems

Turbine Systems

Jet engines run on a system of turbines, where air is forced through to create spinning. The force of the air creates the spin, so much power is needed to lift the jet off the ground. The engines will provide this power, but they need the initial jump to begin spinning and forcing air through. That’s where turbine starting units come into play.

These units are typically portable, mounted to trailers and dragged across the tarmac. They may be mounted to the ground as well. They have a connector that fits into any standard plane, so one power unit can typically service an entire fleet of planes just based on connection type. However, these units have charges and fuel levels of their own. It’s not uncommon to find several hundred of these units in a major commercial airport for efficiency’s sake.

Power in Airplanes

Cars run on batteries, and they are charged as you drive. The battery holds enough of a charge to turn the engine over, then your car does the rest of the charging itself as you move. Planes don’t work like that.

Planes use an auxiliary power unit to power the rest of their system, so you can think of jumpstarting a plan as something you do in phases. The first step is hooking the APU up to the ground unit, then the APU is fired up. That energy is then used to power the remaining flight systems and get the plane ready for take off. An APU is like turning the key halfway on a car. The plan can perform most of its cabin functions, like AC or lighting, but doesn’t have the juice to take off.

Final Thoughts

An airplane starting unit has to meet specific criteria before it can be used on a commercial aircraft. New guidelines demand charging units that have a starting range of up to 43,000 feet, which is related to the altitude where a plane might receive a jump.

Related Story: Auxiliary Power Unit

Why You need Portable Power

November 20, 2018 by admin · Leave a Comment

Have you ever had a bad dream that involved a blackout? Are you the owner of a business who has worried about what would happen to revenues if the power all of a sudden went out? Perhaps, as a homeowner, you’ve seen news stories that reminded you of how bad things can be when you don’t have the power supply you take for granted, but no less rely on.

Fortunately, there are a number of options that can help you sleep well at night. Something like a 28 volt battery pack is a good example of this. A pack like this is highly portable and is full of the electricity you need for charging plenty of large pieces of equipment.

Fortunately, there are a number of options that can help you sleep well at night. Something like a 28 volt battery pack is a good example of this. A pack like this is highly portable and is full of the electricity you need for charging plenty of large pieces of equipment.

However, a portable GPU is an even better option still. You can get all sorts of power from these products and they’ll ensure everything from the lights to an airplane battery can get going when you think all hope is loss. Many use them on a daily basis to get the power they need, no matter what the status of their normal electricity is.

So no matter what your needs may be, portable power can do it all and more.

Portable power units are absolutely critical for many business solutions, but they can also be a real luxury for other purposes too.

Designing a Paging System for Your Business

December 6, 2017 by admin · Leave a Comment

A paging system can help your business relay information quickly, and can be utilized as part of a management strategy to direct employees. A well-designed system allows you to quickly reach employees and get them where they need to be. Here is some advice on how to design a paging system for your business.

A paging system can help your business relay information quickly, and can be utilized as part of a management strategy to direct employees. A well-designed system allows you to quickly reach employees and get them where they need to be. Here is some advice on how to design a paging system for your business.

Basic Requirements

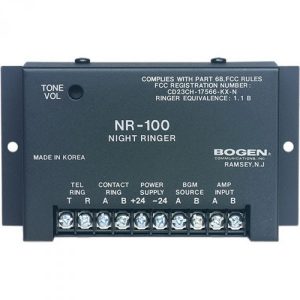

First, you need to determine the basic telephone paging equipment you need to start your system. The first route is cost efficient, and it involves an audio line level signal. Essentially, employees will utilize a code over the phone (typically a star code) to make a universal announcement. To end the announcement, simply hang up the device.

An extension interface, a device that is plugged directly into the phone extension, offers some slightly different functionality. Everyone can call a universal number that is designated for paging. Every page is handled centrally in this method, and it allows for some benefits not found in the cost-efficient method.

Announcements can be made by anyone with access to the number, even if that person is offsite. This is important, as an executive may need to speak with someone who is onsite in order to get critical information. Commands can also direct announcements to different zones.

Final Thoughts

When designing a paging system for businesses, it’s important that announcements get to the people in need of hearing them. For smaller companies, a cost-efficient system can provide quick access to employees. Larger and mid-sized companies need to consider where and how they want to distribute information to employees.

Article written by CAM Electronics. CAM Electronics is a KDI Distributing company specializing in AV equipment for professional use.

Top Factors to Consider When Selecting a Custom Control Center Designer

October 23, 2017 by admin · Leave a Comment

Summary: If you want your IT team to be more efficient, you’ll want to ensure that you command center is designed appropriately.

With so many organizations and businesses looking to remodel, upgrade, or build new command centers, standards are thrown out the window and even the laziest design seems feasible to many. If you’re one of the many businesses looking to establish a command center with a gorgeous showpiece video wall, this article will help you understand the gravity of this type of project.

The Budget

Your investment boils down to what custom designer you’re planning to use. For instance, say you go with a remodel project and you’re starting with a blank slate. You’ll obviously ask questions regarding what the designers are envisioning. Then, you’ll jump into the fray and give them input on what you’re picturing in your head. There cannot be any disconnect between the two of you. If you have a firm budget laid out in your head, don’t keep extending it to the point where it becomes ludicrous. See what these designers can do with a number laid out in front of them. This is where you start separating one from the other.

The Decision

One it’s time to make a decision, how do you make sure that you’re selecting the right consoles or other accessories? The key factor behind this is quality. Now, be honest with yourself, you already know that every manufacturer out there is going to consider themselves “the best in the business”. It only takes the right salesperson to draw you into their business. Be mindful that not every custom control designer has the same mentality when it comes to your project. Lay out a sufficient amount of ideas and goals that you have and provide it to some of the designers that you are interested in. After all, it’s their job to provide you with a customized center that can handle every aspect of your business. Not only do they need to understand your wants and needs but they’ll also need to make it happen.

PVD Coating vs. Gold Plating

May 23, 2016 by admin · Leave a Comment

Both techniques have their own unique advantages to them that offer the user numerous benefits.

In the jewelry business, there are several different processes and techniques used to achieve a gold look. Now, aside from the fake products, two of the more common ways to achieve this appearance are through gold PVD coating and gold plating. Sure, they sound like they’re essentially the same process, but each has their own unique advantages that adapt to certain situations. So, what differentiates the two from each other?

In the jewelry business, there are several different processes and techniques used to achieve a gold look. Now, aside from the fake products, two of the more common ways to achieve this appearance are through gold PVD coating and gold plating. Sure, they sound like they’re essentially the same process, but each has their own unique advantages that adapt to certain situations. So, what differentiates the two from each other?

PVD Coating

Physical vapor deposition, otherwise known as PVD, is a process that occurs within vacuum deposition systems that produce a decorative and functionally beautiful finish. PVD typically utilizes titanium nitride to provide a tough, durable coating layer on top of a substrate. PVD coatings tend to be more resistant to corrosion, moisture, and the other wear and tear features that watch users undergo.

Gold Plating

Gold plating, on the other hand, occurs when a piece of real gold is plated onto another type of metal – say, stainless steel for example. This process is often done as a cost-efficient way to achieve the look of real good. One advantage that gold plating has is that it gives the product the look of actual gold. It’s aesthetically pleasing to the eye and can be used on a variety of products. And, without having to pay thousands more to obtain a thin film vacuum coating, you can save a substantial amount of money. However, gold plating doesn’t have the same durability and resistance that PVD coating offers, leaving its security at the whim of the user.

For the finest in sputter coater systems, visit Denton Vacuum, LLC. A leader in coating technologies, Denton Vacuum, LLC can help you find the perfect system for your next large-scaled project.

Vacuum Metalizing Everyday Household Items

February 20, 2016 by admin · Leave a Comment

The trophies and medals hanging from your walls have that distinct shine thanks to PVD coating.

The process of vacuum metallization is essentially a form of physical vapor deposition. The process requires the combination of both non-metals and metals to evaporate and then deposit into a thin film. The most common metal used in vacuum metallization is aluminum because of its’ thermodynamic and reflective properties.

Advantages

Vacuum metalizing gives off a highly reflective surface that’s similar to chrome. Also, when using aluminum, its low cost enables there to be an increase in production. This process also can be tinted for various colors such as: brass, copper, gold, blue, green, and black chrome.

Vacuum Metallization in Plastic Parts

Visually, if you were to coat a piece of plastic with metal, you wouldn’t expect there to be an increase in both gloss and reflectivity.

Through vacuum metallization, metallic properties such as abrasion resistance and electrical conductivity can also be added to plastic components. Upon completion of metallization, these now-metalized components are treated in the same light as metal plated parts. Although they carry the properties of metals, they tend to be lower in weight and have a high corrosion resistance as well. In addition, the electrical conductivity that now encompasses the plastic part can be controlled to avoid electrical surges.

Physical vapor deposition coating, or PVD coating, can be found in a variety of household items that are commonly found. Products such as: lamp reflectors, emblems, trophies, fishing lures, and advertising display items are only some of the products that are vacuum metalized. The immense amount of gloss and shine are what makes this method stand out.

Denton Vacuum, LLC manufactures premium sputtering systems and PVD systems for any deposition application. Visit their large inventory online today.

Advantages to Vacuum Deposition Systems

April 25, 2015 by admin · Leave a Comment

When you need a thin film of materials, the process can be surprisingly difficult depending on what you want to manufacture. For instance, if you wanted to coat a plastic screw in metals. You couldn’t melt the metal and apply it to the screw, you’d need another method to bond the metal to the plastic. A thin film vacuum coating would allow you to bond the two materials under specific temperatures. There are other advantages to using this technique too.

Temperature Control

One of the biggest advantages to using a system that applies thin film vacuum coating is the ability to control temperature. In the example above, the screw is common for lots of items. Optic lenses, like the kind used in cars or eye glasses, might melt or crack under the extreme temperatures it would take to break the chemicals down into gas. Melting and pouring the material over the glass will leave a coating that is thick and uneven, plus the drying process may create imperfections.

Finish

The vacuum chamber allows the molecules to come to rest on the substrate in an even finish, which frees the surface from physical defects like bumps or bubbles. This is especially important anodizing metal, where the smoothness of the finish is part of the selling point. The finish can also make a difference when it comes to thickness. Thin film means microns in thickness, which requires precision and isn’t something you can fib. Imagine what would happen if a metalized screw were too thick. An entire schematic might be missing a crucial component thanks to a bad finish.

Bio: Denton Vacuum, LLC manufactures a sputter coater used in a variety of advanced manufacturing industries.

The Role of Thin Film Vacuum Coating in Computers

August 29, 2014 by admin · Leave a Comment

Thanks to thin film vacuum coatings, we can produce powerful semiconductors for a lower cost.

Semiconductors rely on conductive material to transfer electricity from one part of a computer to another. This process is constantly at work as you type behind your desk or even when you microwave your lunch for the day. Here is how thin film coatings help manufacturers build more powerful computers and electronics.

Thin Film Vacuum Coating

In order to create the parts needed inside of computers, manufacturers must make specific alterations to the materials they work with. This is how semiconductors conduct electricity. The circuit board isn’t built to naturally conduct electricity, so a thin film vacuum coating is used to cover the board in materials that conduct electricity.

This technique can also metalize parts, which helps to drive down the costs of manufacturing. Small parts, like screws, can be built of plastic and then metalized.

Systems and Applications

The most obvious example of a sputter coater at work is the semiconductor, but it’s not the only one. The process is used in the guidance systems that power rockets headed to space. It’s also in the parts that help those rockets fly. Batteries can also use this technology for highly specialized activities. You will also see this technology at play in the medical sector, where it is used to coat devices that will be used in patients.

Final Thoughts

Thin film coatings are crucial to the development of computers, but the process finds applications elsewhere in manufacturing projects.

Related Story: What is Sputtering?

Related Story: Run by Run Advance Process Control of Metal Sputter Deposition

Denton Vacuum, LLC sells vacuum deposition systems that are helpful in the manufacture of electronics and optics. Find out more about the advanced manufacturing techniques of these devices with Denton Vacuum, LLC online.

How to Launch a Balloon to the Stratosphere

May 20, 2014 by admin · Leave a Comment

Weather balloons used to be science experiments reserved for those with the money to do the research. New technology has not only made the balloon cheaper, but the technology to capture images and data has also lowered in price. Here is the lowdown on how you launch a weather balloon into the stratosphere to collect data.

Payload Construction

You will need an arm to hold the payload that you intend to attach to your high altitude weather balloon, but there are some weight considerations to take into account. In the US, you are restricted to a payload that does not exceed 12 pounds. That twelve pounds must be distributed across the box your payload is housed within, the data logger your payload uses to capture data, and any other attachments you decide to add.

Balloon Setup

Begin in a flat and wide-open space, with all of the components of your balloon kit spread out on a table. Assemble your payload, securing the weather balloon camera to the arm where it can get a good view as it ascends. Also keep in mind that the size of your balloon will affect the volume of gas it will hold, so larger balloons are likely to travel a longer distance and reach a greater height.

Launch Site

The site that you choose should be free from objects that will impede your flight path. Power lines, trees and other obstructions can cause your balloon to catch on its flight path, stopping the journey entirely. Also be sure that you launch on a clear day with low wind speeds. Follow the flight path of your balloon carefully with your GPS unit, and be prepared to make a trek to retrieve the payload.

Ion Beam Sputtering and Electron Microscopy

April 26, 2013 by admin · Leave a Comment

Guest post provided by Denton Vacuum, LLC. Denton Vacuum manufactures machines that employ precision methods like ion beam deposition practical applications such as electron microscopy. Visit www.dentonvacuum.com for more information.

Applications for vacuum coating systems are vitally useful for the electron microscope. Scientists studying sensitive specimens need optics that do not interfere with how the specimen behaves for better controls of the experiment. Electron microscopes use a beam of electrons to create a visible image of the specimen that scientists can then analyze. Electron microscopes have an intensely higher resolution and power than light microscopes, and give scientists the ability to do much more detailed research studies. Conductive coatings provided by ion beams allow prevention of tainting the specimen with a charging of the sample by conducting heat away from it.

There are different types of machines that can produce the coating need for these functions. Among these machines are Sputter coaters, vacuum evaporators, electron beam evaporators, and ion beam sputtering systems. The process is straightforward and intriguing. First, the coating substance is placed with the source material inside a vacuum chamber inside the ion beam sputtering system. Afterwards, with the pressure low, an inert gas is introduced. A Radio frequency strikes the gas, causing it to become ionized. The vaporized gas condenses on the surface of the target in the form of a diamond-like film. This film protects specimens scientists are observing from heat and ionization that can result from the use of a light microscope.

Thin, continuous, and uniform deposition of the coating material is absolutely vital for sensitive samples or samples that are prone to charging. These sensitive samples can range from anything including carbon black powder, immunogold and softwood fibers. Scientists who utilize electron microscope technology need a superior amount of precision offered by quality ion beam deposition systems.